Prepare the materials you need

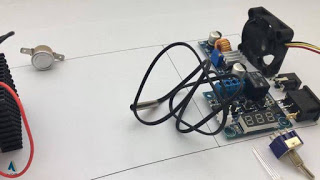

-The materials we need here are: temperature control module, 4mm cooling fan, radiator with fan, a small heat sink, DC5.5 socket, 3 color LED light, temperature protection switch, ship type switch, toggle switch, drop Pressure module, as well as refrigeration film.

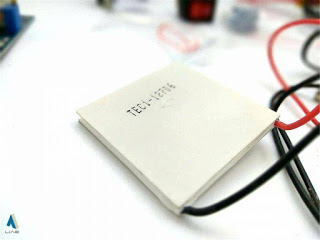

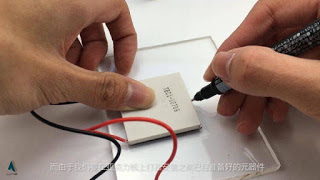

- Semiconductor refrigerating sheet, also called thermoelectric cooling sheet, is a kind of heat pump. Both ends can absorb heat and release heat separately. I think many people have already understood it. I will not introduce it in detail here. But do you think he can only cool? Then you have the pattern. When the two poles are reversed, the hot and cold side of the cooling sheet will be inverted, so that the original cold surface will have a heating effect, and this is what we want.

- "The principle of semiconductor refrigeration film"

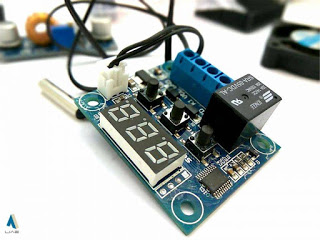

- The temperature control board was bought from Alibaba, because buying a finished board directly will take a lot of roads. However, because I accidentally bought a 5V power supply version, the seller suggested that the voltage is 6V, so I have to add additional power, this next talk

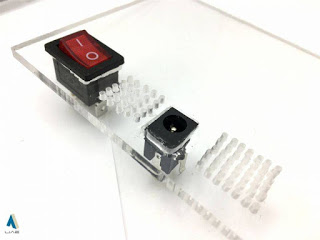

- Switch for switching, here I use a boat switch with a maximum current of 6A, and a double 6-pin toggle switch for switching hot and cold gears

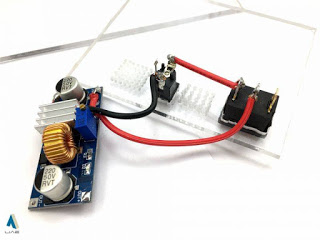

- The buck module uses a nominal 5A, maximum 75W module to limit the power of the cooling chip

- Use a three-color common cathode LED as an indicator

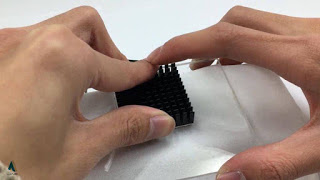

-Used a radiator on a colorful God card G210, a 4mm square heat sink and a 4cm diameter cooling fan

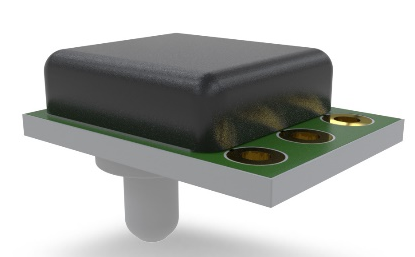

- In addition, use a 80 ° C normally closed temperature control switch as a protection switch

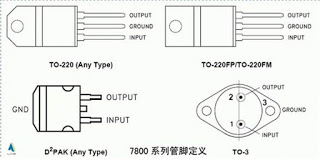

-7805 is a common linear three-terminal regulator integrated circuit, its preset output voltage is 5V, and the middle of his pin is actually the sampling end, as long as the voltage of this pin can be changed to change the output voltage, so we A 1N4007 diode with a voltage drop of 0.7V is connected in series to boost the voltage of 0.7V.

- Figure 7805 pin definition

[size=18.6667px]- After the transformation, we finally managed to use the 12V power supply to illuminate the temperature control board without worrying about the overvoltage of the relay.

Start making

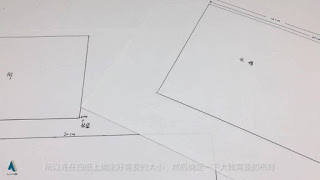

- Next we have to make the shell, because we need to cut the acrylic sheet, so first determine the required size on white paper.

-[size=18.6667px] and then determine the layout that is roughly needed

- Cut acrylic sheet, use hand saw, hook knife or other convenient cutting equipment. It is also a good choice to customize a acrylic shell.

- After the cutting is completed, we can tear off the protective tape layer attached to the acrylic, oh... I remember that there is a saying that the tear film is so cool.

- When the protective film is torn off, you can see the golden acrylic sheet.

-Because we have to pre-install the components on the acrylic plate before the hole is installed, in order to ensure the accuracy, we must determine the required hole position before punching, in order to ensure the subsequent normal installation of each component, so lift Oily pen in hand

- After drawing the punching position, it is necessary to actually operate. Here, I opened the human meat carving machine mode and used the hand drill to complete the punching work. Of course, everyone has better tools. It is naturally excellent, and the manual punching is very good. Prone to error

- Finally, the shell is finished, you can breathe a sigh of relief, and then it is assembly work. Start with the big part and insert the refrigerating piece into the already opened hole.

- Use 704 and 705 silicone rubber for heat conduction, sealing and waterproofing to prevent water leakage or excessive temperature at the hot end of the refrigerating piece

- After waiting for the silicone rubber of the heat sink to harden, the cooling piece can be tested. Since it has not been immersed in water, we first determine the voltage at a lower power to prevent the downstream burning of the cooling piece.

The components of the left wing are installed, and the next part is the right control part. First, the DC socket for power supply and the ship type switch are fixed at the opening of the side plate.

- Then close the eyes with intensive phobia, and put a dense vent on the switch and socket to enhance the heat dissipation of the buck module.

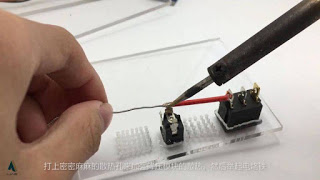

- Then lift the soldering iron, connect the switch to the DC socket, and connect to the DC step-down module to complete the power supply.

- Paste the fan on the rear side and the silicone rubber for temperature protection

영어

영어  중국어

중국어  독일어

독일어  한국어

한국어  일본어

일본어  Farsi

Farsi  Portuguese

Portuguese  Russian

Russian  스페인어

스페인어