Instead of spending money on off-the-shelf modules, manufacturers refer to the application circuits that control the IC, using discrete components to build a switching voltage regulator and mount it on a circuit board.This method is effective in theory, but there are some problems in practice.

On the face of it, a fully functional switching voltage regulator can be achieved by mounting the latest generation of 2x2mm control IC on a printed circuit board along with discrete components recommended by the manufacturer.That seems logical, too.In theory alone, this should be the lowest cost to get the equipment running efficiently.Unfortunately, in practice it turns out that things are not so simple because the devil is in the details.

Handling dynamic load

Chipmakers often come up with circuit designs based on the somewhat optimistic assumption that most of the loads are static, and therefore these designs have very few discrete devices.In fact, static loads are often an exception to normal functionality.Load cycles with a ratio of 1:1 million are common, such as when the microcontroller switches to sleep mode.

Excess energy causes a rapid increase in voltage in the capacitor.Initially the controller switches the on-time to zero.If the inductor still has some energy, the output voltage cannot be controlled properly.In devices with low output voltages, it is also possible to double, unless the capacitance is much greater than the recommended value in the specification.

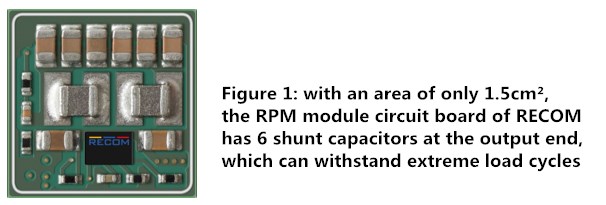

Solutions for discrete devices do not easily overcome this problem.In the RPM series design, there are six shunt capacitors to buffer the output (figure 1), which is far beyond the chipmaker's recommendation.This configuration is standard for all models in RECOM's new RPM family.With several small ceramic capacitors in parallel, the surface area can be much larger than with a single large capacitor.Therefore, heat can be more efficiently transmitted from IC and inductors to the GND plane.Another advantage of this design is that it reduces the ESR of the capacitor.

How to improve EMC

Although the above approach can overcome the dynamic load problem of discrete device design, EMC presents a greater challenge because the performance of the filter is determined not only by the controller IC, but also by the layout of the entire printed circuit board.This is why IC manufacturers usually do not offer advice.Because device designers often know little about the interaction between IC and PCB, they cannot predict whether a circuit will pass an EMC test.

EMC problems with high switching frequencies become more important as designers need to reduce the size of inductors.Joseph Fourier shows that square waves can be rendered as infinite sine waves of higher frequencies.The higher the switching frequency, the greater the number of harmonics, and therefore the higher the possibility of resonance affecting inductors and capacitors within the PCB.

Figure 3: PM5.0-6.0 electromagnetic radiation;Pm5.0-6.0 is equipped with a Class B external filter, as recommended in the data manual.

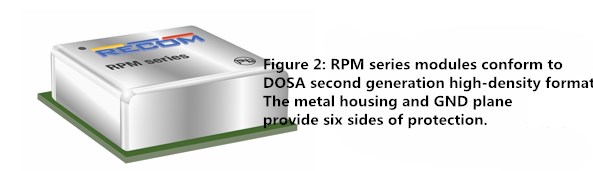

Power module is the product of EMC optimization design and certification.For example, the RECOM RPM series of modules are equipped with a 4-layer PCB with a base layer and a metal housing providing appropriate shielding on six surfaces (figure 2).As a result, these modules provide excellent EMC data.The specification includes information about simple SMD ferrite beads that enable modules to reliably conform to Class A or Class B specifications, which has been verified in RECOM EMC lab tests (figure 3).If the quality of the main power supply and the distance between the load and the module can be reliably controlled, it may not even be necessary to use magnetic beads.

Good thermal management requires four layers

Having successfully overcome all the problems just described, designers of discrete device solutions now need to consider heat dissipation.The compact design of modern controller IC makes it difficult to dissipate heat.However, heat dissipation is critical for long life and reliable ambient temperature values.

The 4-ply plate is the most suitable solution because of the GND plane as the radiator.It is more economical to use off-the-shelf modules for devices with two layers large enough to hold all the components.For example, the RPM family of RECOM has optimized heat management capabilities.

At the RECOM research and development laboratory in glendon, engineers spent months developing a solution that combines the best electronic design with the best thermal design.Now the RPM module's 12x12mm circuit board has many advanced cooling features, including various through holes designed as heat pipes.While this technology is not cheap, it ensures that the heat from the BGA IC and passive components is dissipated in the most uniform manner to the metal housing and GND plane.

With this method of innovation, partnered with set up the new global standard again, because the RPM module can be in the absence of derating at ambient temperatures as high as 105 ° C and reliable work, only through the shell &gnd plane heat dissipation.The most powerful RPM modules can provide up to 6A current, and the "50W/cm3" power density is about 50% higher than similar modules provided by other suppliers.

Other advanced technical features

The RPM series includes non-isolated SMD switching voltage stabilizer modules designed according to the latest technical standards.At present, modules have 3.3v and 5V outputs and currents of 1, 2, 3 or 6A, and can be combined with external resistors to achieve output voltages between 0.9v and 6.0v.Ultra thin modules, 97 to 99 percent ultra high efficiency at full load.Modules are also extremely efficient, especially in the 5-20% load range (figure 4)

Figure 4: in the actual test, the new switching voltage stabilizer achieved excellent efficiency in the very important low load range -- -99% Max!

Allow the highest temperature is also very high, such as no external heat 1 a model can absorb up to + 107 ° C temperature.The switch regulator module has many additional functions such as soft start, timing and output voltage tracking.RPM series modules are manufactured by fully automated European chemical plants and can be ordered through normal distribution channels.The maximum price of the module is about 4 euros, and the specific price will be adjusted according to the order quantity.

Assessment boards that shorten the development cycle

Manufacturers can choose modules over discrete device designs for DC/DC converters to develop prototypes smoothly.The latest RPM series has 25 pads, each of which is only about 1mm2.To facilitate prototype evaluation, RECOM has developed a special evaluation board that integrates the switching voltage stabilizer and all its functions, and an external filter assembly has been installed.Therefore, all evaluations can be performed easily without welding.

conclusion

Although highly integrated controller IC makes it easier to produce non-isolating switch voltage stabilizers, off-the-shelf modules are generally a better choice.On the one hand, modules shorten the development cycle.On the other hand, they reduce the risk of EMC test failure.In addition, they are a single component in the bom and do not require separate components purchased from different vendors.Finally, it is also important that they no longer need to attach controller chips smaller than 2mm2 to PCB.Attaching chips to larger components is not always easy, but placing them next to larger components can be a challenge.

영어

영어  중국어

중국어  독일어

독일어  한국어

한국어  일본어

일본어  Farsi

Farsi  Portuguese

Portuguese  Russian

Russian  스페인어

스페인어