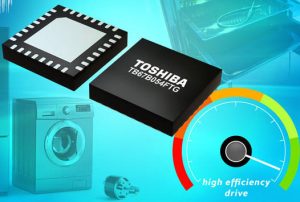

Toshiba has launched a three-phase brushless fan motor controller IC for white good, intended to increase efficiency drive and reduce noise.

“Conventionally, motor control is carried out by a microcontroller and an 8-pole rotor using a rotation-control signal that delivers 3 pulses per cycle,” said the firm, “Switching from an 8-pole to 12-pole rotor achieves higher drive efficiency and reduces system noise.”

The controller, the TB67B054FTG, can control the rotation speed of a 12-pole rotor with a standard microcontroller system by using a rotation-control signal that delivers two pulses in a single cycle – and rotation control for a more conventional 8-pole rotor can also be implemented.

Since the rotation-control signal outputs two pulses in one cycle, the current rotation-control system for 8-pole rotor can be applied to 12-pole rotor, according to the firm.

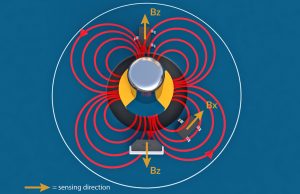

Externally, the chip needs three Hall sensors, a host MCU and a power bridge.

Drive is sine-wave, although during start-up the motor is driven by square-wave commutation signals that are generated according to

the Hall signals. When the hall signals indicate a rotational speed of 5.7Hz or more, the chip estimates the rotor positions from the Hall signals, then generates sine-waves by comparing the modulated signals against a triangular waveform. The data sheet explains this and the two pulse system in detail.

It comes in a 5 x 5mm 32pin QFN type package, saving space over its existing three-pulse-per-rev product (TB6584FNG/AFNG) which comes in a 10.2 x 7.6mm SSOP30.

Both ICs run on voltages from 6-16.5V (18Vmax).

Mass production has begun.

Source from:electronicsweekly

영어

영어  중국어

중국어  독일어

독일어  한국어

한국어  일본어

일본어  Farsi

Farsi  Portuguese

Portuguese  Russian

Russian  스페인어

스페인어